27 February 2024 – Shell Nigeria Exploration and Production Company (SNEPCo) has successfully completed the first remotely controlled well completion operation offshore Nigeria.

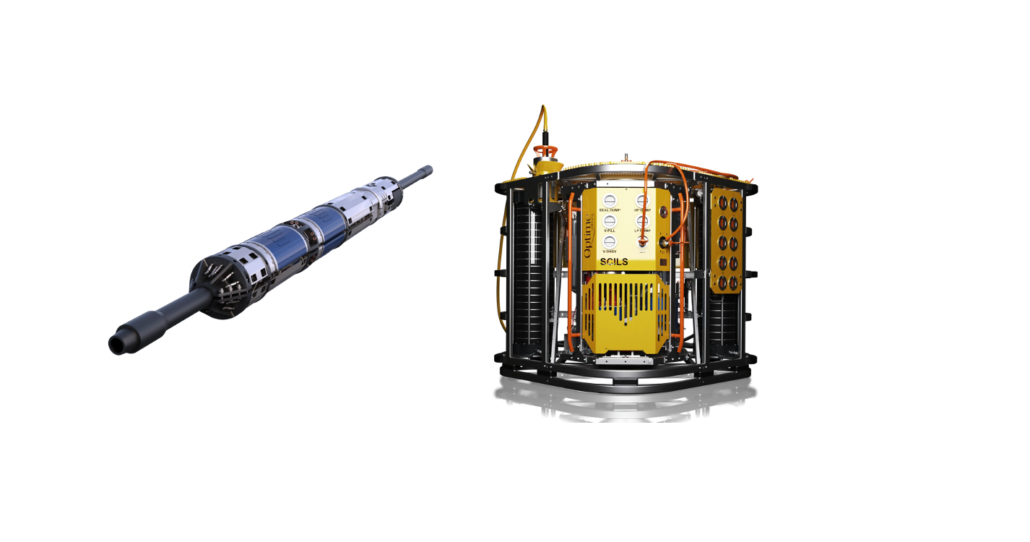

The operation was performed at the Bonga field, in 1,060 metres water depth. The well completion operation was performed utilizing a Remotely Operated Controls System (ROCS) that has been supplied by Norwegian technology company Optime Subsea.

Optime Subsea’s ROCS eliminates the need for both the umbilical, which traditionally connects the surface to the seabed for controlling the tubing hanger in subsea well completions, and the topside hydraulic control unit. This innovation not only cuts costs but also significantly reduces the amount of deck space required for these operations.

“We are very pleased with the performance of the ROCS. It means that we can perform well completion operations quicker, at lower cost, and with substantially lower CO2-footprint compared to conventional systems,” says Justus Ngerebara. Lead Well Engineer at SNEPCo.

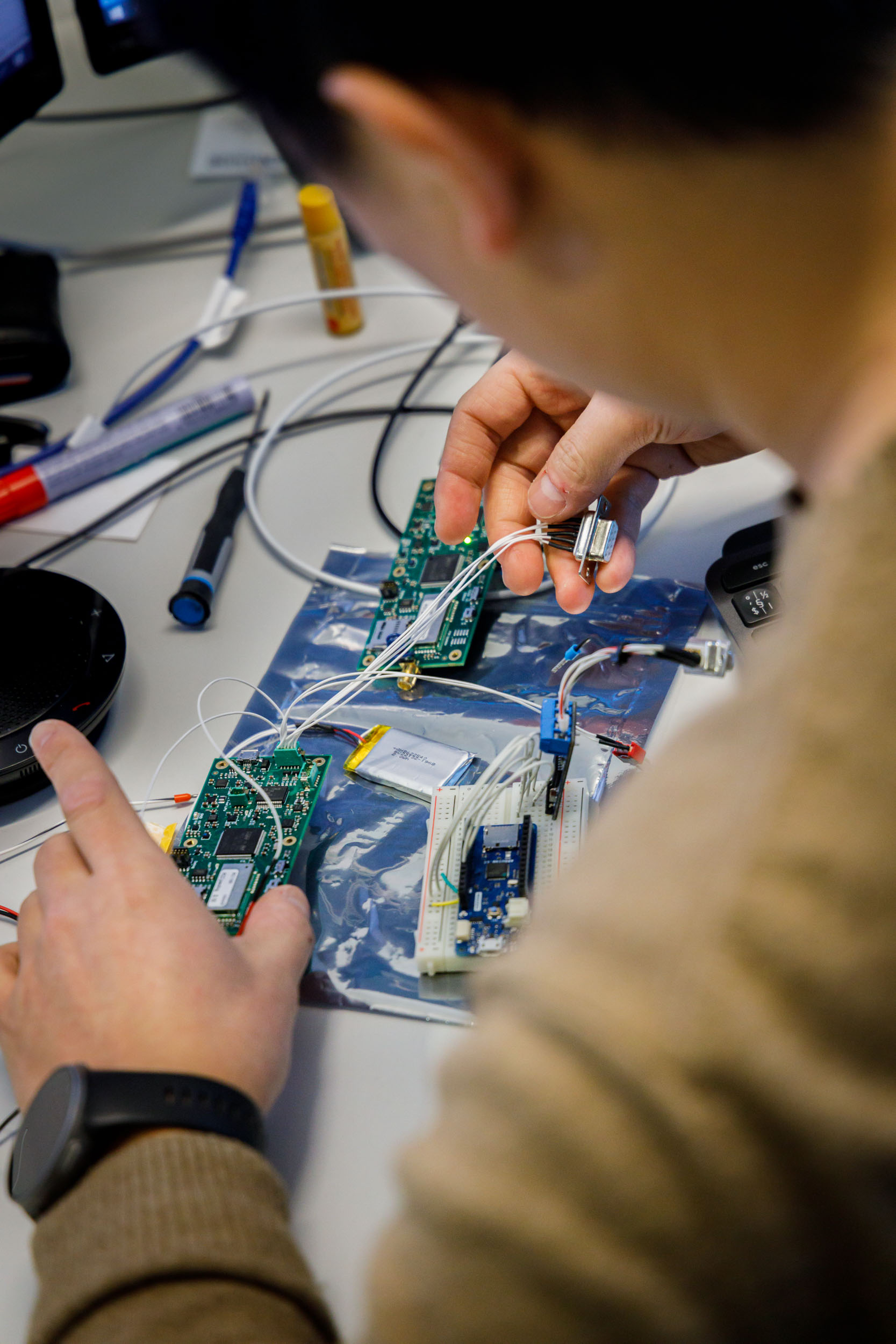

Last year, SNEPCo took delivery of its first ROCS from Optime Subsea and have worked closely with Optime Subsea to integrate the system into its operations.

Using a ROCS means that operators can cut approximately 50 tonnes of equipment from their offshore transportation list, which means substantially lower CO2-footprint. It also means reduced operating time and less HSE exposure on the drill floor. In total, it reduces both CAPEX and OPEX for operators.

Optime Subsea has performed multiple ROCS operations in the North Sea and Gulf of Mexico, but this was the first in African waters. The operation was led by Optime Subsea’s operation in Nigeria, supported by personnel from the company’s headquarter in Norway.

“To be able to free up valuable deck space immediately after the operation, through shipping the ROCS to shore, is a significant advantage for the rig operator. We are delighted to bring this technology to Nigeria and very grateful for SNEPCo’s innovative and ambitious approach to subsea well completion operations,” says Rodger Hooker, Chief Service Officer at Optime Subsea.

Optime Subsea has offices in Notodden, Norway; Houston, Texas; and Lagos, Nigeria. Over the past decade, the company has established itself as a leading specialist on subsea intervention and controls systems globally.

ROCS details:

- When completing subsea wells, the tubing hanger is placed on top of the wellhead, as a seal towards the rest of the subsea well.

- Normally the tubing hanger is controlled through a dedicated hydraulic umbilical which adds a large 20-30 feet control container. When running the umbilical, it is also clamped to the tubing for increased stability.

- ROCS replaces these operations by remotely controlling a controls unit toward the wellhead. This allows for safer, simpler and more efficient operations.

- ROCS is mobilized in a single basket, prepared and made up onshore, allowing it to be ready to run immediately when offshore, from a rig. Avoiding mobilization of 50 ton + of topside equipment

- The ROCS is 100 percent universal and can be applied to any type of subsea well.

For additional information, please contact:

Trond Løkka

Chief Innovation Officer |Optime Subsea AS

E: tl@optimesubsea.no| NO: +47 97705528 |