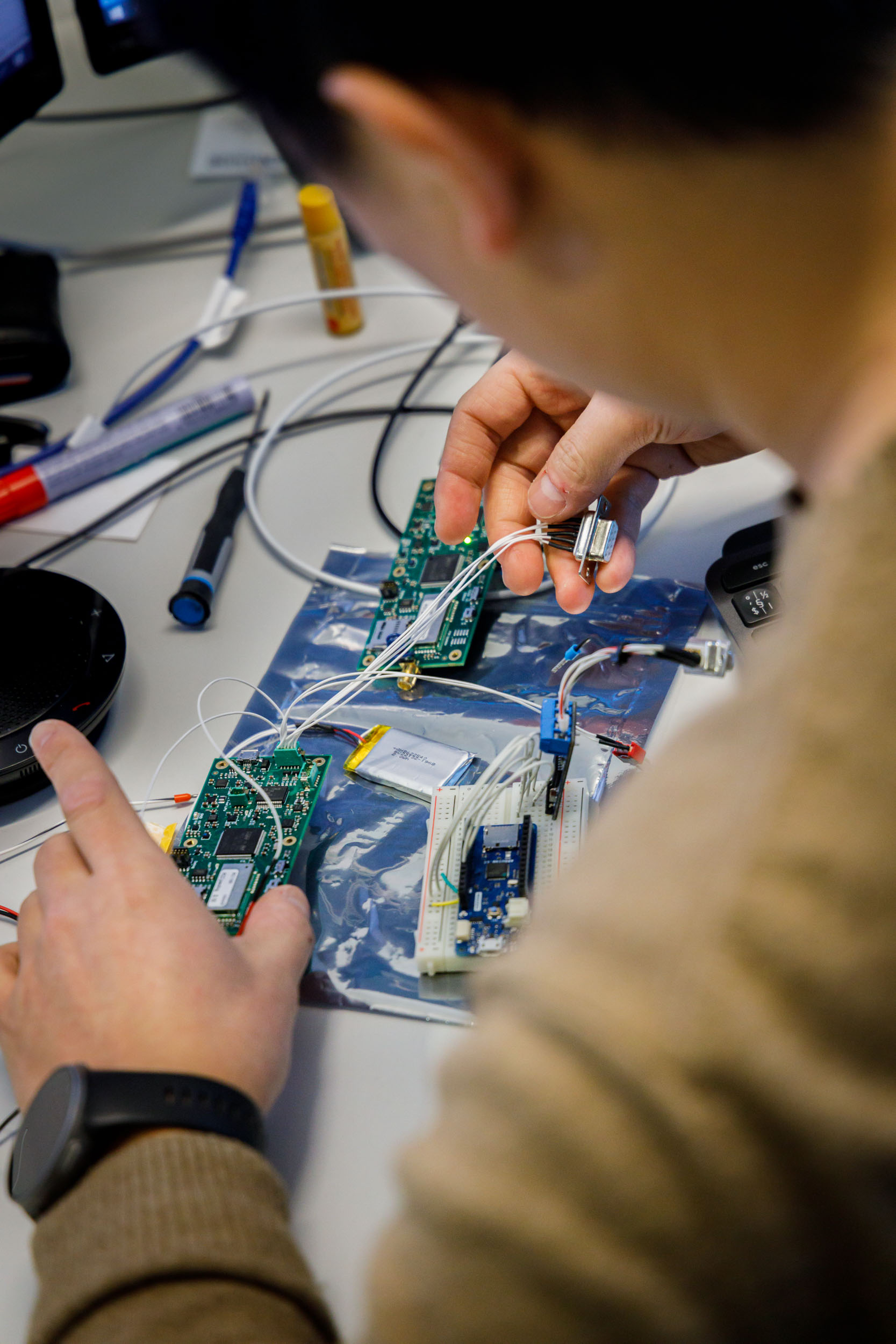

Erlend is now working as a full-time project engineer at Optime Subsea. He started his career at Optime Subsea during his studies at USN Kongsberg. Erlend studied Systems Engineering, specialized in Software. The young engineer has already been a key contributor to the development of the mSHPU, SCILS and ROCS products. He has lent his talent over the whole stack, from driver-development, through controls-engineering, and to the top layer of human machine interface.

I was wrong.

– In 2011 I was offered to play for NFK – Notodden Fotball Club. I lived in Trondheim, one of Norway`s biggest cities and I saw myself as a city boy. I hesitated and was slightly negative when I moved to Notodden. My opinion of this small town was that there was nothing to do. My initial plan was, therefore, to return to Trondheim, Trøndelag.

Can you tell us what made you change your mind?

– After a while I realized that Notodden had the whole package. The city is surrounded by astonishing nature and had a lot of activities. Notodden is simply an idyllic place to live with its good reach to more central areas like Drammen, Oslo, Skien and Porsgrunn. Since my partner is from Notodden and I now work at Optime Subsea, I find my life here enjoyable.

As you enter the door at Optime, you get the opportunity to set your mark.

Erlend

Why did you want to work at Optime Subsea?

– When I got hired as a software engineer, Optime was smaller than today. I immediately experienced the Optime spirit, drive and commitment that has brought us to where we are today. My ambitions were heard and acknowledged from the first day, and I was given room for creativity. Optime is intentional when hiring, and it is all about finding just the right people. In this way Optime takes care of the culture, that which contributes to the success of the company. With Optime, you have the opportunity to make a significant contribution to its further development.

Freedom and creativity

– In my role as a software engineer at Optime I work closely with other people and disciplines. From start to finish, you gain essential knowledge as a participating part in different projects. It is the opportunity to develop myself and the company that keeps me thriving. Optime does not put you in chains, but instead gives you flexibility and freedom.

- Optime Subsea`s mission is to be the market leader in subsea intervention and control systems. Our mission is to be the leading provider of systems for subsea intervention and control, within the oil and gas industry. We will accomplish this by continuous innovation, with focus on productivity, modularity, and optimization – always to and for our customers.

As a Software Engineer, you might have prejudiced thoughts of the industry

The oil – and gas industry is not known for being a forward – leaning industry within software.

In Optime we want to be innovative in everything we do. Our slogan “We simplify subsea” permeates everything we work with, and together as a company we strive to break limits continuously. It is evident in our projects like ROCS and SCILS where this is demonstrated. Both projects that needed electronics, and software knowledge to make the control system.

If you are a software engineer and thinking about working at Optime – I have one advice; leave an application!

Optime are innovators in the industry, and I can guarantee you will find this journey an enriching one to be a part of.

Erlend

Exciting Projects as a Software Engineer

– NUI was exciting because it was my first project. The responsibility I was given from the beginning made me have to trust myself and believe in my decisions. These projects leave you with experience and pride. By taking part in processes like these and working through them from start to finish, you gain an understanding of planning, execution, and the context.

ROCS is high-level innovation within oil and gas. I got to be a part of this project from start to finish. Out on operation, it was amazing to see the result of every hour and day of work.

Using the new technology was a real success!

Your attitude is important!

– The only thing I look for when hiring is attitude. For us, this means being eager to learn and not shying away from responsibility.

Optime will further innovate the industry with its disruptive technology. If we are to innovate the industry and maintain the pressure with new ideas, we also have to innovate ourselves – become better. It is a prerequisite that we hire different types of people; To ensure diversity and good questions.

Are we too similar, then we will not be innovative enough.

Erlend

Erlend – Outside Optime

– I am very fond of staying active. Before covid hit, I played football, as well as skiing. I am always active, no matter what the season is. Having moved to Notodden, we now have access to a lot of great opportunities and offers throughout the year.

– The fact that Optime able to dissuade me of moving back makes my partner very happy. As am I to this day. And as a father I am not interested to live anywhere else but right here. We are very happy, and we are looking forward to establishing at Notodden.

Optime became the anchorage for Notodden and the reason why we have established ourselves here.

Erlend